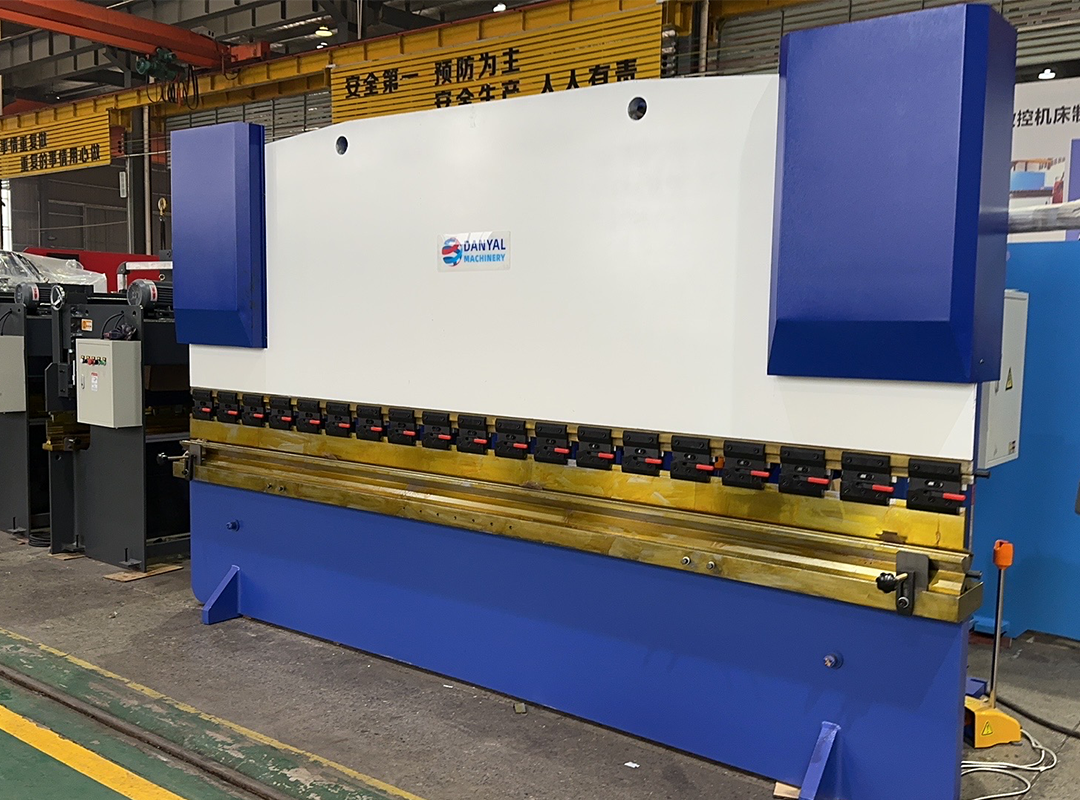

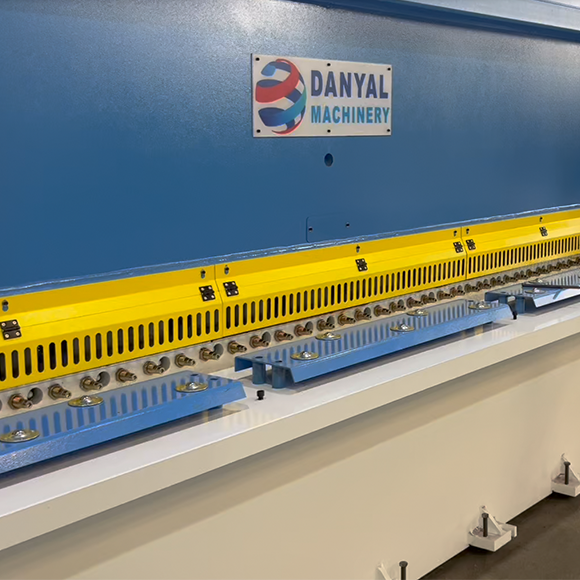

Screws Production Line

Danyal Machinery screws production line , all what you need make your required screws.

The connections between the crankshaft and the body and the impact connecting rod are all connected by high wear-resistant alloy copper tiles, which have large bearing capacity, long service life and low maintenance costs. The machine body is cast by adding alloyed ductile iron 500, with high tensile strength and good wear resistance.

The working principle of the thread-rolling machine is to reciprocate the dynamic thread-rolling die plate by the bending arm, and the workpiece is pressed by the interaction with the static die plate. It can accurately grind various standard thread teeth of national standard, ISO, DIN, JIS, ANSI, BS, GB, etc. The machine has the advantages of rapid speed and good stability, and the minute capacity can be up to about 300pcs. It is advanced thread machine with higher speed in the current market. It can also design coil abnormal screw and abnormal hardware and metal products especially according to customers’ requirements.

The heat treatment process alters the internal structure of the metal by heating to a certain temperature and then being cooled in a certain manner to obtain the desired degree of physical and mechanical properties such as hardness,

brittleness and softness.

The temperature metals are heated to and the rate of cooling after heat treatment can significantly change metal’s properties.

Our YouTube Channel

Related Machines

You may also like